The rapid adoption of supply chain automation technologies in India is transforming the future of warehousing and logistics as we know it .

In 2019, the warehouse automation market in India was valued at INR 202 billion. The market is expected to expand at a compound annual growth rate of 13.38% during the 2020-2024 period, to reach a value of INR 421.5 billion by 2024.

The rise in e-commerce demand amidst the Covid-19 crisis has led to the need for faster, smarter and efficient supply chains with higher responsiveness and accuracy of inventory management. According to the 'Indian Cold Chain Industry Outlook 2022', the Indian cold storage and supply sector is poised for a growth compound annual growth rate of 17-18 percent till 2022. The growing shift in purchasing behaviour is primarily being driven by the bio-pharmaceutical, agriculture and organized food retail sectors.

Warehousing Automation Technologies-

The rising need for the implementation of warehouse automation has resulted in the increasing adoption of cutting-edge proptech technologies in the logistics sector. This transition from costly human labor to a technology-focused operation is called "Warehouse Digitalization."

Here are some of the most important warehouse automation technologies now being adopted in India:

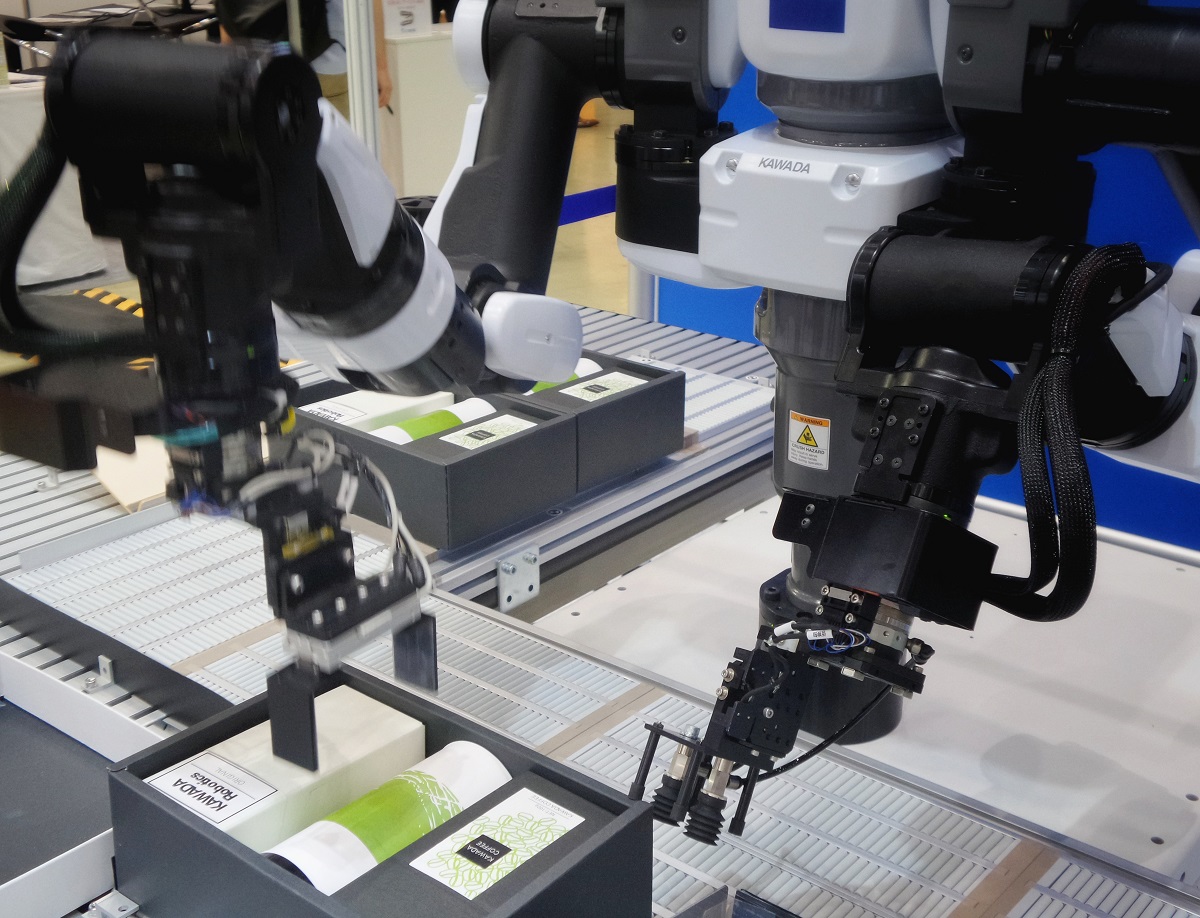

Autonomous warehouse mobility solutions:

The application of automation in warehouse logistics facilitates conducting mobile operations at the click of a button. Mobile automated guided vehicles (AGV) in warehouses help streamline the supply chain and reduce costs as they ensure efficiency by operating in predefined pathways, transporting products for storage or dispatch 24 hours a day, 7 days a week and 365 days a year.

Internet of Things (IoT):

The internet of things refers to an interconnected ecosystem of devices all connected via sensors that can acquire and exchange data in real-time. Smart warehouses or Smart Warehouse Management Systems (WMS) utilize the IoT concept to allow for completely visibility of all inventory-related aspects of the warehouse via tools for tracking inbound and outbound goods, documentation of all transactions, reporting of stock quantities, monitor the health of machinery, assess efficiency of employees and much more.

IoT-enabled enabled technologies can also accurately track and monitor essential factors such as temperature and moisture control. This is critical in the Covid-19 scenario to support the exponential demand for temperature-controlled warehouses by the pharmaceutical industry. These technologies also help prevent theft or malpractices and allow for planned and organized activation of labour.

Mobile computing and wearable tech:

Mobile wearable tech refers to hand-held or pocket-able computing devices which can be used to report information and disseminate all data across along every step of the operational process. This improves operational efficiency, reduces wasted travel time and provides real-time data, facilitating quick and informed business or operational decisions.

Business Intelligence:

Business Intelligence refers to the analysis of data collected by the Internet of things architecture, presented in a format that is easy to understand by comparing current and historic data. This data serves as the backbone of the warehouse management systems, allowing decisions makers to make accurate and informed decisions in a timely manner.

Artificial Intelligence:

Predictive analysis using Artificial Intelligence has become the need of the moment in today's scenario. Artificial Intelligence processes massive amounts of data to enable machines to perform tasks such as decision-making, speech recognition, special awareness etc, using machine learning and statistical predictive models. Predictive analysis refers to the use of data sets created by AI to read patterns and trends and predict future outcomes. This provides operations with adequate time to take planned action.

Block chain:

Block chain is a digital ledger technology containing "blocks" of data "chained" (linked) and shared across all computers in a network that allows for secure exchange of records between parties. The block chain database is transparent and distributed among all parties, ensuring a high level of security and accountability. By creating a single data platform instead of different complex technologies, seamless collaboration between entities in the supply chain can be achieved. Additionally, when paired with IoT implementation, all incoming data can be automatically updated on the unified block chain ledger.

Warehousing Automation in India is the critical driving force that is making warehouses more efficient, improving cost-effectiveness and boosting productivity. The future lies in digitalization of the warehousing sector.